Advantage:

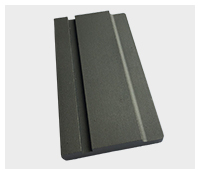

Sintered samarium cobalt is prepared from the raw material metal bismuth-cobalt and a series of elements, smelting, milling, pressing and sintering. SMCO has high temperature resistance.

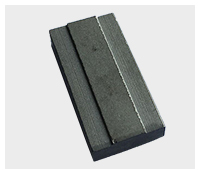

Low temperature coefficient: The temperature coefficient of Br is: -0.035% / °C, and the temperature coefficient of iHc is: -0.2% / °C.

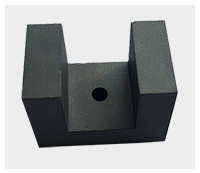

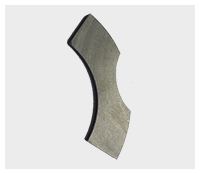

The largest production size of the product: 120x120x100mm, 100mm direction orientation magnetization.

SmCo permanent magnet is a superior permanent magnet material with high magnetic properties, strong corrosion resistance, oxidation resistance, low temperature coefficient, high Curie temperature and high ambient temperature.

Disadvantage:

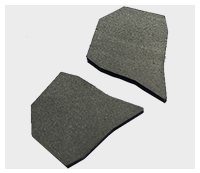

1. Sintered samarium cobalt materials have brittle properties and lack ductility. SMCO5 is easy to process and SM2Co17 is more fragile.

2. SMCO permanent magnets should be careful during the assembly process to avoid any irons to prevent mutual attraction and cause the magnet to break.

3. Sintered samarium-cobalt materials may cause minor defects due to slight collisions during production, packaging etc.

4. If the use environment is bad, such as acid and alkali environment, it can be protected by plating with Ni, Zn, epoxy and other coatings.