Bonded SmCo:It is a synthetic magnet produced by a process of pressing and injection molding of samarium cobalt magnetic powder and polymer.

Application:Computer and office automation: HDD, CD, DVD-ROM spindle motor, printer, fax machine stepper motor, etc.; automotive field: permanent magnet starter motor, direction assist motor, automatic window motor, seat adjustment motor, brushless DC motor , speed sensor, etc.; household and electrical appliances: watches, air conditioner stepper motors, cameras, camera drive motors, etc.;

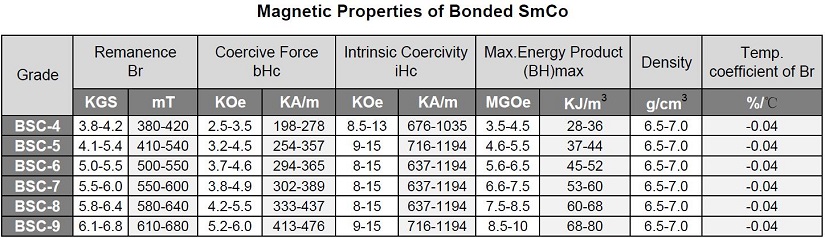

Isotropic pressing bonded smco :It is made by mixing samarium-cobalt magnetic powder with a polymer material and pressing it into a permanent magnet product of various shapes by a die. It has the following characteristics: it can be magnetized in any direction, and is suitable for making a radial or axial (end face) multi-pole magnetized magnet. Once formed, the accuracy is achieved. Various shapes and specifications. It has strong corrosion resistance and generally does not require surface treatment. Has a high temperature stability.

Anisotropic pressing bonded smco: The anisotropic samarium cobalt magnetic powder is mixed with a polymer material, and a magnetic field orientation is applied during the molding process to be pressed into a permanent magnet product of various shapes. It has the following characteristics: it can be used for axial or radiation orientation, which greatly improves the magnetic properties. Once formed, the accuracy is achieved. Various shapes and specifications. It has strong corrosion resistance and generally does not require surface treatment. Has a high temperature stability.

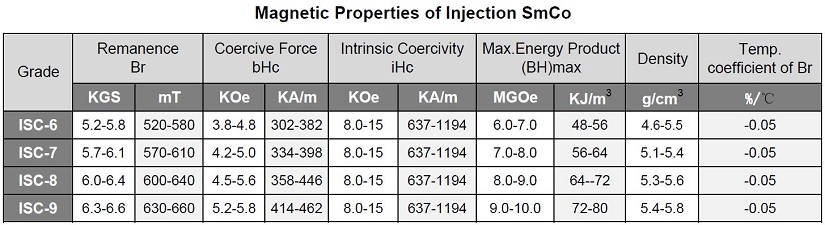

Anisotropic plastic bonded smco:It is made by mixing anisotropic samarium cobalt magnetic powder with polymer plastics (PA, PPS, etc.), applying magnetic field orientation during molding, and injecting into permanent magnet products of various shapes. It has the following characteristics: high performance can be achieved in the orientation direction. One-shot molding of complex shapes is possible. It can be integrally molded with inserts such as shafts or bushings to reduce the assembly process and improve assembly accuracy. It has strong corrosion resistance and generally does not require surface treatment. Has a high temperature stability.